Material

· Bronze

· Pure copper

· Stainless steel 316L 316 304 Ferrite type

· Iron type

· Inorganic type (soda glass etc.)

We will deliver it by plating treatment, fluorine treatment, passive film treatment, acid or alkali wash, ultrasonic washing etc. according to your request.

Binderless stainless steel sphere powder filter

Do not use mix during molding (binder less) A new stainless steel filter has been made.

For general SUS sintered filters, mix binder and wax of material powders to prevent wear of the molds and shape deformation of molded products after pressing. However, they may remain inside the filter as residues after sintering, which can adversely affect the performance of the filter.

Since the “binderless stainless steel spherical powder filter” developed by our company is molded and sintered without using any mixtures, impurities will not remain after completion.

It is ideal for analytical instruments and fuel systems that require higher purity filtrate.

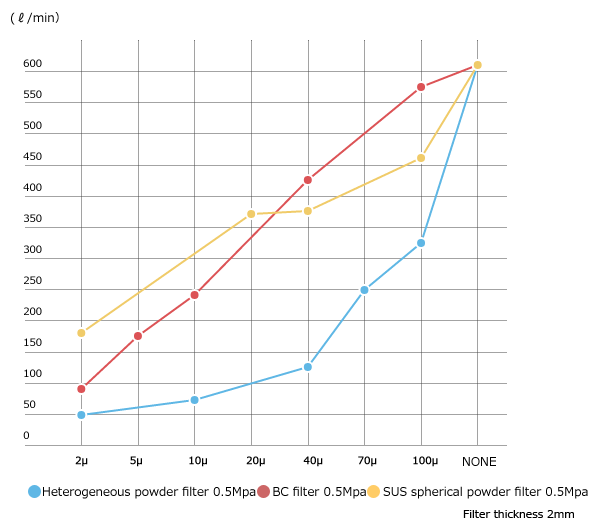

· Comparison of flow rate (equivalent to nominal filtration hole 10 μ / cup type / thickness 2 mm sample)

| Type | Water flow rate(ml/min.) | Air flow rate(ℓ/min.) |

| General sintered filter (using heterogeneous powder) | 26 | 370 |

| Binderless sphere powder filter | 31 | 651 |

| About 20% UP!! | About 40% UP!! |

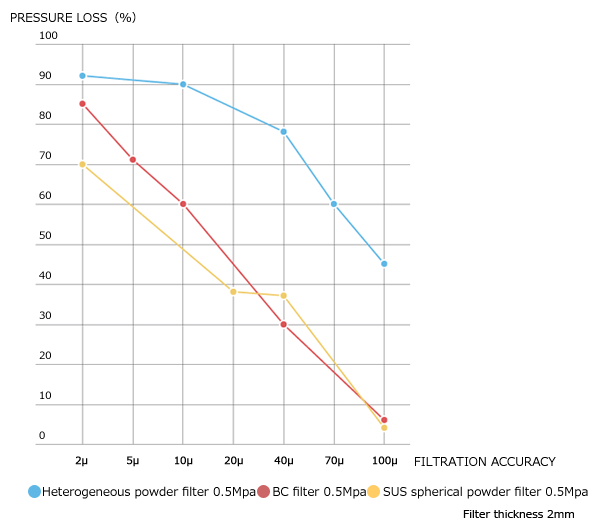

Our SUS spherical powder filter uses SUS spherical powder as a material and it has very low pressure loss compared with conventional general SUS sintered filter and can reduce the burden on peripheral equipment.

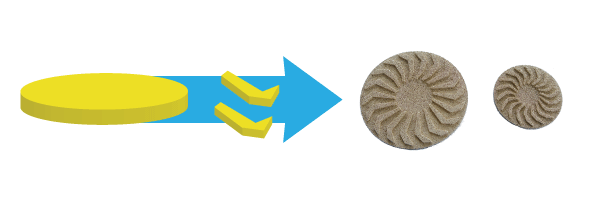

Minimum filter

Diameter 1.4mm Thickness 2.0mm

Pressure loss data

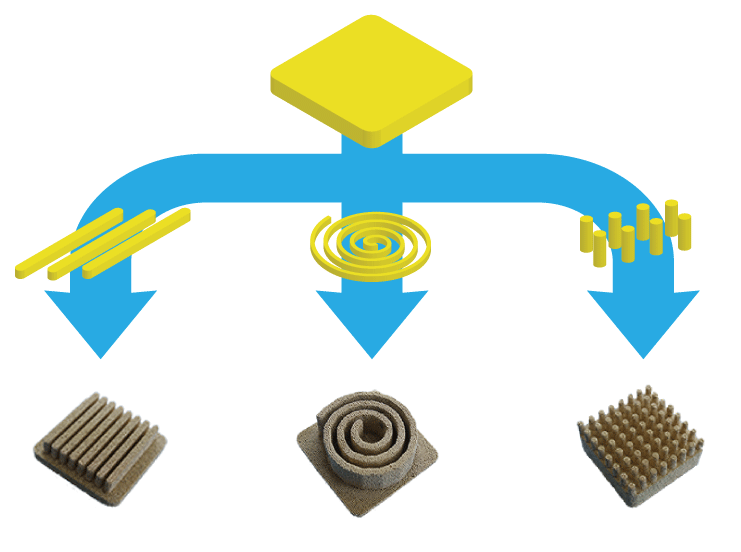

Simultaneous sintering

| Conventional | Simultaneous sintering |

|

* Slit is co-sintered, secondary processing |

|

|

Integral molding

Multiple parts constituent parts combined by welding, caulking, screwing etc. can also be integrally molded by sintering.